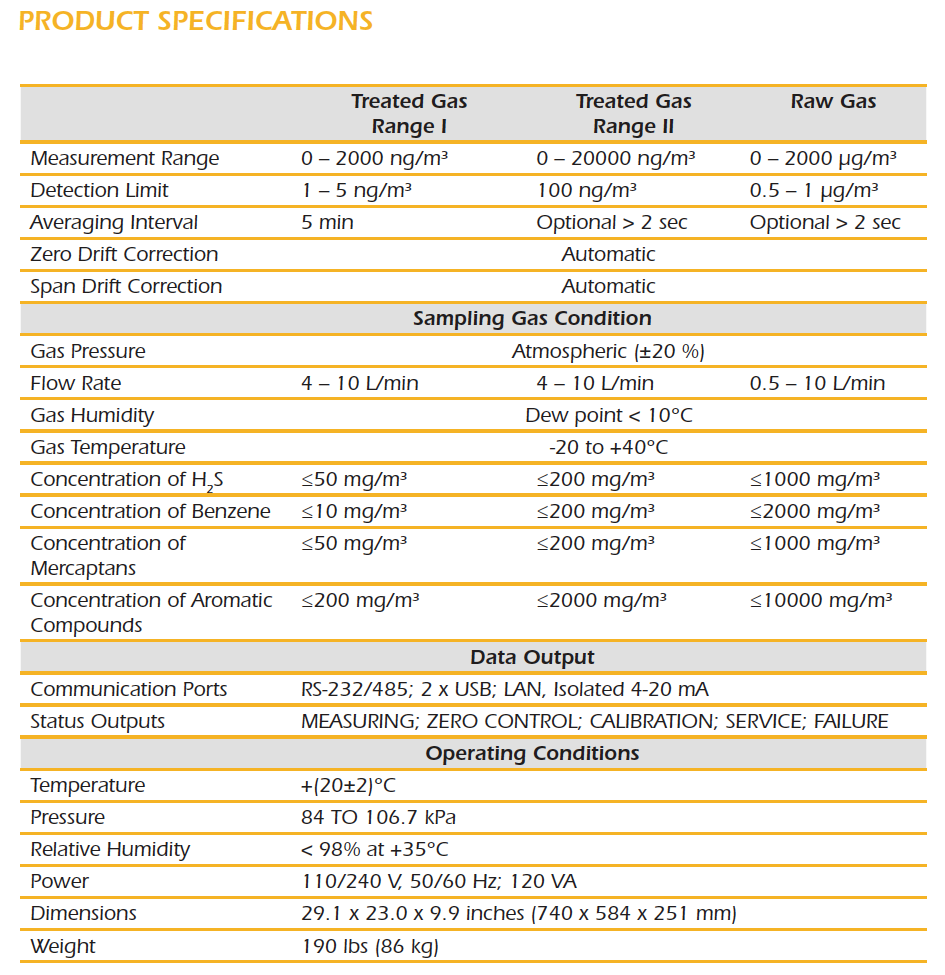

The AMNG-EXP Automatic Mercury Monitor for Natural Gas is designed for continuous, on-line measurement of Mercury in the gas flow. The spectrometer, operating computer, filters, valves, electrical connections, and power supply are located inside an explosionproof, ATEX certified enclosure. The AMNG-EXP Monitor is designed for indoor operation, or installation inside a climate controlled room. The embedded operating computer controls the measurement procedure, data processing, and data transfer via RS-232/485 interface or current loop.

Spectrometer: The AMNG-EXP features a highly sensitive, atomic absorption spectrometer with Zeeman background correction, providing interference free measurements.

Sample Lines: The inlet and outlet ports of the Monitor are equipped with 6 mm compression fittings for connecting to 6 mm OD (1/4”), 4-5 mm ID, Teflon PTFE or PFA tubing.

Data Acquisition / Communications: Built-in industrial grade computer, real time readings with Excel data file or direct communications with DCS via Modbus TCP.

On-line remote data transfer and analyzer control/calibration capabilities.