The study of cryogenics has been a fascinating branch of physics for over two centuries and just mentioning the word conjures up images of everything from cold, boiling nitrogen vapor to the perfectly preserved body of Walt Disney (a fallacy but nonetheless fascinating). Cryogenic research was initiated when Scottish physicist William Thomson (Lord Kelvin) realized the relationship between gas volume and temperature could be extrapolated backward, resulting in zero volume at a very low temperature. That temperature is now known as “absolute zero”, the temperature at which all molecular motion ceases to exist and is about -273°C (-459°F), or simply zero Kelvin (0 K), the temperature scale named for Thomson. Quantum physics later refined the definition of absolute zero to include ground state energy, but for all practical purposes the concept and temperature scale remain unchanged today. The field of cryogenics is mainly concerned with temperatures very near absolute zero, within milli-Kelvin or micro-Kelvin of zero, but all cryogenic research passes through the warmer regions of low temperature and yield valuable lessons that can be applied to liquified natural gas (LNG) at about 113 K (-160°C or -256°F).

Gases exist in nature as a group of molecules moving at relatively high speed, occasionally colliding with one another, but otherwise having little or no interaction with one another. The speed of the molecules are proportional to temperature on an absolute scale (which is why the Kelvin scale is appropriate) and lighter molecules move faster than heavier ones. As the temperature of a gas is decreased, the molecules slow down and weak attractions between molecules become more significant. These interactions draw the molecules closer to one another as the temperature is lowered until finally the molecules liquify, meaning the physical state changes from gas to liquid. The attractive force itself is usually the van der Waals force, named for the Dutch physicist Johannes van der Waals, and varies from one molecule to another depending mainly on the electron shell structure of the molecule. Heavier molecules with polar structures tend to liquify at relatively high temperatures (for example water liquifies above room temperature) whereas light molecules liquify at lower temperatures (for example helium liquifies at about 4 K). Liquefied Natural Gas (LNG) is a mixture of methane, ethane, nitrogen, and a few other molecules and although relatively warm compared to liquid helium or liquid nitrogen (77 K), it is generally referred to as a cryogenic fluid within the energy industry.

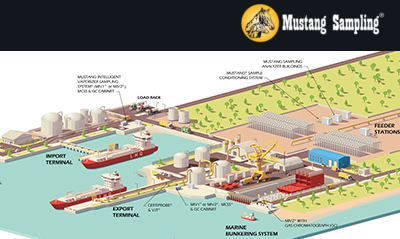

LNG is created to facilitate easier transportation and storage of natural gas when pipelines are not available. Countries without energy resources depend on shipments of LNG to charge their natural gas grid from which residential, commercial, industrial, and electric power producers derive energy. LNG Sampling is the process of extracting LNG in a liquid state, vaporizing the liquid, and then measuring the composition using a gas chromatograph analyzer to determine the suitability of the gas for use and its monetary value. Since the vaporizer itself is handling a cryogenic fluid, the design of the probe, tubing, and vaporizer inlet must conform to cryogenic standards.

LNG sampling research and development depends heavily on a core knowledge of cryogenic design principles. These can be broken into broad categories including materials, vacuum technology, refrigerator cycles, heat flow, and electronics. While volumes have been written on each of these topics, the fundamentals are easily described. Material selection in cryogenic systems for LNG can ignore all superconductive concerns since ordinary metals are not superconductive at temperatures warmer than liquid nitrogen. Embrittlement is a primary concern along with material connections, either between similar or dissimilar materials. Thermal strain can be significant at all junctions and ordinary joining techniques and materials may not be suitable. Most commercially available connectors are not rated for low temperature use so custom solutions are common. Sealants in particular can be problematic since many solidify at lower temperatures and simply do not perform their intended functions. Vacuum systems are critical in cryogenics to provide the best possible thermal isolation between components at extremely different temperatures. It is not uncommon for components separated by fractions of an inch to vary in temperature by 300 K. Vacuum technology enables superior insulating capabilities for LNG sampling systems. Vacuum jacketed tubing is an order of magnitude better as an insulator than conventionally wrapped systems. Refrigerator cycles play a key role in lowering the temperature of fluids within cryogenic processes from start to finish. Because of its low boiling point and availability, nitrogen and sometimes helium play an important part in most cryogenic refrigeration cycles. The control of heat flow is critical to maintain any cryogenic system. The largest challenge in LNG sampling is the constant introduction of flowing LNG into a system that is much hotter (its sole purpose is to vaporize the LNG by adding heat), while maintaining the liquid state of the LNG itself as required by ISO 8943, the standard governing LNG sampling. Additionally, the source of the flowing LNG is a pipeline which regularly experiences flow rate, temperature, and pressure fluctuations of its own. Since temperature changes as small as 0.1 K can create pre-vaporization within the system, controlling heat flow throughout the system is particularly tricky and requires years of testing to achieve a suitable design.