BIOMETHANE, RENEWABLE NATURAL GAS, AND BIOGAS ARE ALL PART OF THE CIRCLE OF LIFE

Biomethane is a term for purified pipeline-quality fuel and interchangeable with the term Renewable Natural Gas. These 2 terms refer to biogas that has been cleaned and conditioned to remove or reduce non-methane elements such as H2S, H2O, CO2, N2 and other various contaminates. Biogas is produced from various biomass sources through a biochemical process, including anaerobic digestion. Once biogas is cleaned, it can be used as transportation fuel, generate electricity, or injected into the current natural gas pipeline for heating and cooking. For the most part biomethane/RNG is carbon-neutral and can even have a carbon-negative rating. By capturing methane and converting it into a useful source of energy, RNG use helps to significantly reduce greenhouse gas emissions

Most of the completed biogas projects in the United States whether livestock, wastewater or landfill that would otherwise have been released into the environment as the organic material decays are typically within a mile from a natural gas interconnect. This allows the biogas to easily be upgraded to clean Renewable Natural Gas with a direct pipe connection into the current natural gas grid. These systems are economically feasible with proper sample conditioning systems, analyzer buildings, and injection or shutoff/rejection for both the biogas producer and the end user.

A good majority of the new biogas systems are outlying biogas producing facilities which are usually 30 to 200 miles away from a potential end user or an existing pipeline. These biogas producers cannot easily or cost-effectively connect directly to a gas pipeline. Multiple obstacles such as permitting, environmental issues, neighborhoods, whatever the reason there is no viable option to run a pipe. This is where the “virtual pipeline” comes into play enabling biogas producers to capture value by delivering their product to market. The biogas is compressed Renewable Natural Gas (Biomethane) into a tube trailer and transported from the point of generation to the point of injection or end use.

For Biogas to be pipeline ready it needs to be scrubbed of all deficiencies, contaminants or constituents present such as water, carbon dioxide, oxygenate, sulfur compounds, and solvents. Usually, the first process is a feed blower skid system which increases the pressure as part of the thermal gasification process to prepare raw materials for treatment and compression. Feed blowers pair seamlessly with gas dehydration equipment and help mitigate the high moisture levels at the beginning of the RNG refinement process. The gas is pressurized typically between 5-to-15 pounds per square inch gauge (psig), then is usually chilled by a heat exchanger. The cold gas is sent to the appropriate moisture separating equipment, then reheated to be transported to the subsequent process of removing the present deficiencies. A vacuum blower is used in conjunction with the feed blower. The vacuum blower utilizes centrifugal or positive displacement blowers, which creates suction on the negative pressure side of the CO2/methane membrane to recycle the permeate back to the feed blower for further refining.

A feed gas compressor skid is used to raise the pressure of the gas on the positive-pressure side of the CO2/methane membrane separation system. The two types of compressors typically used for this step are rotary screw or vane compressors which can usually achieve pressure increases up to 350 psig. Feed gas compressor skids may also utilize an inlet knockout/moisture separator to protect the compressor and downstream equipment. Additional moisture removal and gas polishing can be integrated after the compressor to further prepare the feed gas for the membrane system.

Clean and dry purified RNG is compressed to be transported via the preexisting utility pipeline network systems. At this stage, the pipeline gas quality is approximately 95-to-99% methane content. Similar to the feed gas compressor, reciprocating or screw mechanisms are used to compress the gas. These tools help compress clean and dry RNG, prepare it for analysis by a Gas Chromatograph to measure RNG flow and energy content of biomethane.

ALGAS-SDI TRUXX: MAKING GAS ACCESSIBLE, EASY TO USE

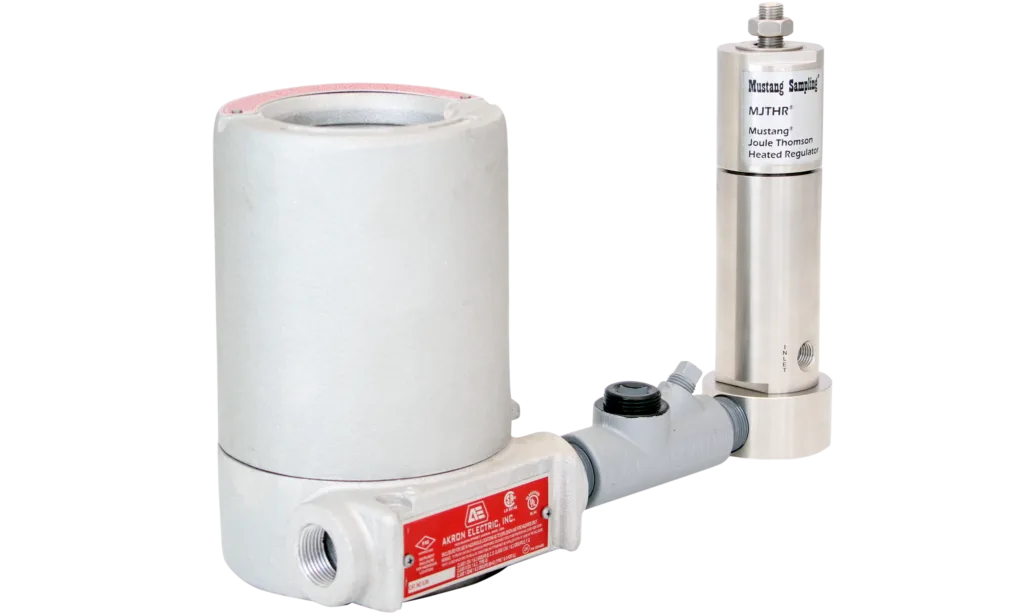

Virtual pipeline applications see the RNG compressed up to 4,000 pounds per square in a tube trailer and transported to an interconnect site. The well proven Algas-SDI TRUXX decompression equipment heats the compressed RNG and injects it into the transmission line or distribution system. The TRUXX system heats the gas via a dry electric or gas fired waterbath heater to counteract the refrigeration effect caused by the expansion of the gas (Joules Thompson effect). The TRUXX system also incorporates a Mustang Sampling instrumentation package and custody transfer flow meter. Because the Algas-SDI TRUXX system packages the heater, meter, Mustang Sampling instrumentation kit and regulation into one 20 foot container, customers can start flowing gas a mere 6 hours after receiving the equipment on site.

It is common for multiple TRUXX decompression systems to be installed at one interconnect site to allow the developer to utilize RNG from many different sources. Some interconnect sites operate at high pressure (>700 PSIG). In order to “drain” the compressed RNG trailer as much as possible and reduce the number of trips to/from the gas production site (farm or landfill), the Algas-SDI central control system incorporates a booster compressor. When the pressure in the trailer is greater than the pipeline pressure, the gas simply flows freely into the pipeline. But when the pressure in the trailer is below the pipeline pressure, the Algas-SDI control system diverts the gas to a booster compressor where its pressure is elevated to allow injection into the pipeline. Algas-SDI’s patented control system also modulates the amount of gas injected into the pipeline from each TRUXX unit, which minimizes the amount of time for a trailer to decant.

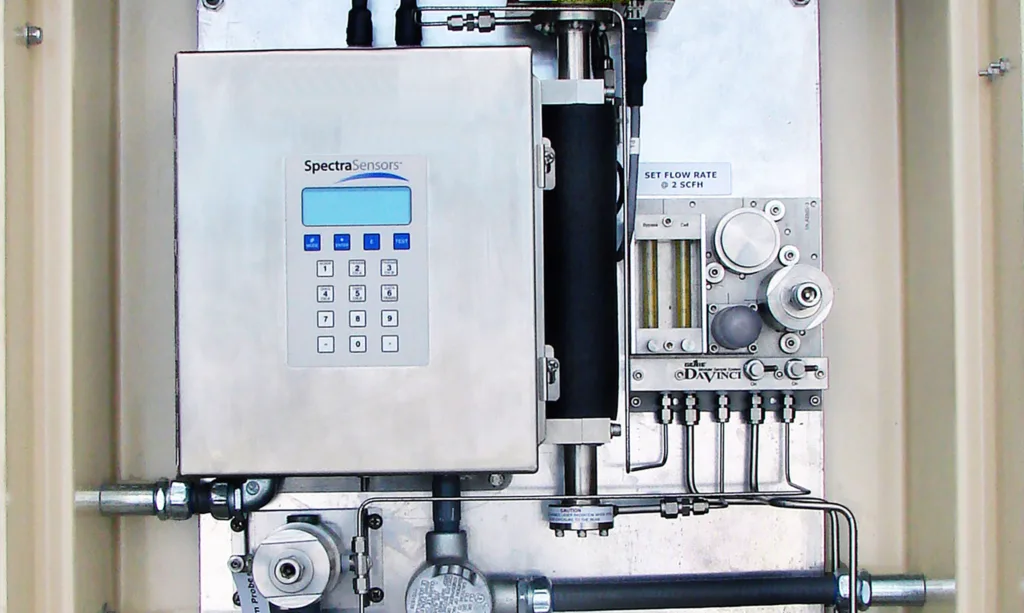

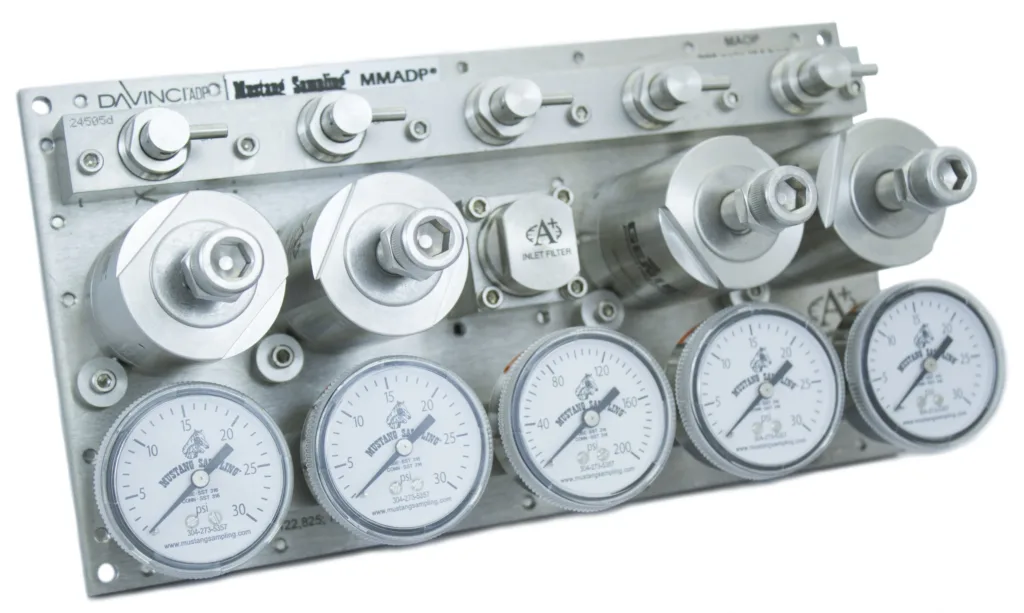

Measurement and control are accomplished utilizing an Analytically Accurate® System integration within the skid using multiple Mustang Sampling products to determine the efficacy of the RNG and reporting/recording any contaminates/constituents present in RNG. Each source of compressed RNG runs through a Pony® Probe Enclosure and transferred using Mustang’s Heat Trace Tube Bundle, to a Mustang Modular Analyzer Distribution Panel (MMADP®) which distributes the conditioned gas samples to a Mustang Moisture Analyzer System (MMAS®)and Rosemont® 370 XA Gas Chromatograph. The separate samples are to ensure compliance with the health-protective standards. Once the RNG is decompressed down to the required pipeline pressure, passes all local tariffs and requirements it is injected into the natural gas pipeline grid.